Steadily evolving over two decades, the manufacturing execution system (MES) now plays a central role in achieving manufacturing efficiency and effectiveness. The MES also commands potentially valuable sources of information for strategic business applications that feed on enterprisewide intelligence.

For nearly 20 years, computerized manufacturing execution systems (MESs) have played a central role in effective manufacturing management. Originally designed to provide first-line supervision management with a visibility tool to manage work orders and workstation assignments, the MES has evolved into the indispensable link between the full range of enterprise stakeholders and the real-time events occurring in production and logistics processes across the extended value chain.

There are major business issues driving the expanding use of these systems, including demand-driven manufacturing, real-time enterprise objectives, and intelligent enterprise applications. Less adversarial and more inclusive managerial approaches, such as collaborative planning, forecasting, and replenishment (CPFR) and collaborative manufacturing product life-cycle management (PLM) have greatly expanded the user audience that depends on MES information support to do their jobs. MESs are integral to the intelligent enterprise because they manage and record the events in processes and logistics as they're occurring, providing an information source that's current and accurate in near real time.

In this article, I'll describe the essential functions of an MES, focusing on aspects that will be important to organizations as they expand MESs use to achieve business and managerial objectives. Although the names given to the various components of the MES vary greatly among industries and even among companies in an industry, the functions and the information collected in the systems fall into similar categories. Most broadly, the MES is the collection of business processes that provide event-by-event, real-time execution of the planned production requirements — that is, the calculation of how many and what to produce — as received from the enterprise resource planning (ERP) level. A more narrow definition would be that an MES serves as a work-order-driven, work-in-process tracking system that manages and monitors production events and reporting activities.

Manufacturing Pyramid

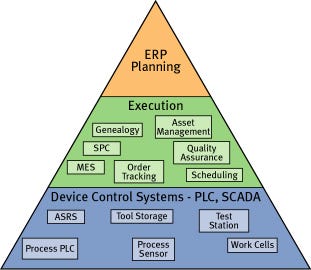

Manufacturing experts have traditionally employed a three-level pyramid to illustrate the hierarchical nature of systems within the manufacturing enterprise (see Figure 1). The lines between the layers are becoming less distinct as vendors extend their applications, but the current condition in most plants will resemble this structure.

FIGURE 1 Hierarchy of systems within the manufacturing enterprise.

The sidebar, "Major Manufacturing Systems," outlines systems shown in Figure 1. Together, the sidebar and Figure 1 closely match how most companies operate their manufacturing systems. The planning level is the realm of aggregated production planning decisions, including for most supply chain activities, such as planned/actual production and inventory quantities. IT usually implements and manages planning systems, which can range from a simple, single-plant MRP system to the most modern, ERP application. The standard view of these systems generally follows a broad perspective concerned with corporatewide macro issues, including financial planning, aggregate inventory data, human resources management, and customer relationship management (CRM). Planning systems are generally used to provide decision-support information or respond to managerial issues on an exception basis. The emphasis is on system standards, consistent data presentation, and data roll-up functions such as accounting and inventory.

Plant floor applications are very different. These operate in an OLTP world and focus on optimizing and accomplishing current operational requirements within minutes, seconds, or milliseconds. The execution level is far more granular, providing the real-time use of tools and systems to manage manufacturing as it's occurring, and then reporting actual results to the planning level. Organizations have typically implemented applications on a system-by-system basis in response to requirements defined by department managers, manufacturing engineers, or equipment/process vendors. These systems have highly varied applications that might include retrieving and applying a process on a machine tool to make a specific threaded hole from a stored part program; measuring and adjusting an oven temperature on a minute-by-minute basis; changing a machine load schedule because received materials didn't meet quality requirements; or turning on valves to deliver liquid material in response to the product recipe. Very detailed inventory information and/or specific variances from standard at each manufacturing operation are typical.

A major role of the execution system is to collect and collate data from the real-time processes for delivery to planning level systems, including ERP and CRM. As the idea of the intelligent enterprise has grown, so too has the focus on expanding the use of MES to provide supporting information.

The third level in Figure 1's general hierarchy is the control level, where device processes are accomplished. This level typically includes the most basic process events, such as turning on motors, measuring temperatures, or making test measurements. Most of these events don't require human intervention but are executed with software logic in the programmable logic controller (PLC) or supervisory control and data acquisition (SCADA) component.

Although planning system suppliers are moving closer to the plant floor, and plant-floor systems are moving closer to planning system functions, the convergence of the two — the assumption of real-time event management by planning system vendors or conversely, the plant-system vendors assuming the business systems view — is unlikely anytime soon. The technology being applied is more than a little different. The issues viewed and the user needs are vastly different. Most often, planning system implementations are totally integrated to work with their own internal modules from a common database, whereas the plant-system infrastructure is made up of a wide assortment of disparate legacy systems and manual methods that few organizations could discard or change quickly without extreme cost and severe production disruptions.

MESs have many different forms and formats. Although MESs are in widespread use throughout most industries, the systems are rarely described similarly nor are the functions identical. An MES in use at an electronics manufacturing facility is similar only in concept to one used in the food processing industry, and they will both differ substantially from the requirements of a pharmaceutical manufacturer. They vary greatly within industries, within companies, and many times between plants within a company.

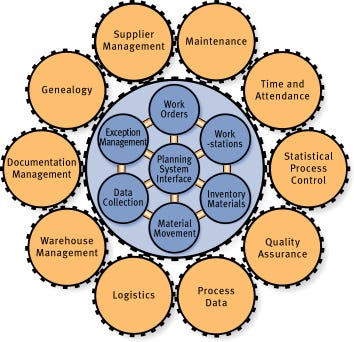

Despite such disparities, some similarities exist regarding general form and function. System components can be divided into two categories: core functions, which are directly associated with managing the production process and included in most vendor packages; and support functions, which are somewhat peripheral to the central order management process. Figure 2 illustrates MES functions, using the notion of a system of gears.

FIGURE 2 Manufacturing execution system functions.

Core Functions

In order to provide a better understanding of MES and the integral role it plays in executing business objectives, I will briefly review the system's core functions here:

Planning system interface. This function describes the connection with the planning system (ERP) and defines how and what information is exchanged.

Order management. This function includes the accumulation and management of work orders that have been received from the ERP system. This function performs the following common tasks: making changes (such as quantity) to orders; combining or splitting orders; running short-term what-if analyses to determine best current resource use; and prioritizing and scheduling.

Workstation management. This function is responsible for implementing the work order production plan, workstation scheduling, and the logical configuration of each workstation. The current resource availability along with the current schedule requirements by operation are normally maintained here.

Inventory tracking and management. This function develops, stores, and maintains the details of each batch, lot, or unit of inventory of the work-in-process.

Material movement management. Either manually or automated, organizations schedule and manage the movement of material through this function.

Data collection. This segment acts as the collection point, clearinghouse, and translator for data that is needed and/or generated on the plant floor.

Exception management. This function provides the ability to respond to unanticipated events that affect the production plan, such as a bill-of-materials item shortage for a work order in process. Most MESs include the ability to react to exceptions following rules that are typically plant centric. Exception management generally requires some level of configuration or customization in order to meet local requirements.

Support Functions

The following identified MES functions are only a representation of possibilities and aren't an exhaustive list of what's available or in use:

Maintenance management. Sometimes called "asset" management, this function manages production equipment maintenance-related issues, including predictive maintenance, work order and labor scheduling, procurement and storage of the repair parts inventory, and equipment-record maintenance.

Time and attendance. Systems usually include clockin/clockout information along with labor data collection and employee skills data.

Statistical process control (SPC). This quality control method focuses on continuous process monitoring rather than the inspection of finished products.

Quality assurance. These packages may or may not be tied together with SPC and/or ISO 9000 systems. Separate or combined, quality assurance packages are frequent components of the production process.

Process data/performance analysis. Process data collection and management can be a standard package developed for specific applications, such as time/cost variance information or manufacturing process records.

Document/product data management. Product data management can be a very large component of the manufacturing system used to create product drawings and process information and then supply that data for plant-floor use.

Genealogy/product traceability. Genealogy and traceability are similar functions designed to provide a complete history of a serialized item or a group of items. In addition to the locally generated production data, most systems can include similar information on each bill-of-materials item going into the finished product.

Supply chain management. Suppliers can be connected to supply a wide range of information. Data may include information about genealogy, schedule, quality assurance, and logistics.

Warehouse management. These systems are primarily for monitoring and managing outbound inventory activities, with some systems also capable of inbound raw or purchased material management. Product location information and order fulfillment instructions are two of many online functions. Sometimes called "supply chain execution" systems, they can include logistics and other traffic management data.

As stated earlier, MESs can come in all shapes and sizes and have one or more of the components outlined here, depending on the industry and user company. Some companies have all of these systems and more, but don't use the term "MES." In other instances, a company might call a single module — such as an SPC package — an MES system. Others will have an assortment of packages collectively referred to as an MES, but have no tie between the packages. MES doesn't have a broadly accepted meaning, especially among batch and process industries. It's also important to note that while core functions will generally be well integrated, most of the support functions won't. Newer applications pay more attention to data integration issues, but most execution systems are made up of disparate components.

Leveraging MES Information

Although in widespread use since 1985, business objectives for efficiency and efficacy in the supply chain are driving a surge of new interest in their MES applications and usefulness. A major reason is that these systems (both manual and computerized) and their components generate and maintain a large amount of data that could be useful to many more people within the enterprise as well as external value-chain partners on both the demand and the supply side. Historically, this information has been difficult to retrieve and include in more extensive user communities — that is, those beyond the plant floor. The good news is that information availability is improving as vendors recognize the need to enhance their applications with broader functionality, Web access, and newer tools that can collect and aggregate data from disparate systems.

In an upcoming article, I will focus more closely on how organizations will use MES data and information more broadly for IT systems. Briefly, here are some leading-edge ideas some organizations are using to broaden the use of this information:

Portals can aggregate and process manufacturing data for specific user communities. Portals can be used to share scheduling information across collaborative value chains.

Manufacturing intelligence systems can collect specific data from plant-focused devices and systems. Such systems can present information in dashboards and other KPI tracking systems.

Progress in business process management tools and application standards, such as RosettaNet, will improve linkage among global MES functions and support organizations building composite applications to serve the plants of a company and/or companies within a value chain.

Execution system providers are broadening their application footprints by offering greater functionality in their existing systems, or by providing additional, linked application packages. Rockwell Automation, GE, and Siemens are good examples of companies that have acquired an array of companies and products, enabling them to build integrated, single-source solutions for their business partners. Additionally, traditional MES technology providers, including Camstar, Datasweep, and Visiprise are extending their systems to include improved support for a wider variety of functions, including quality assurance, genealogy, product life-cycle management, and supply chain collaboration.

MESs have been in place for many years, with a primary focus of supporting first-line supervision. As the systems' use broadens to support a wider audience — a trend implied by intelligent enterprise and value chain collaboration concepts — the MES role will change. One key role is clear: The MES will have a growing impact as a critical source of real-time event information.

Michael McClellan is president of Collaboration Synergies, an advisory company focused on collaborative manufacturing systems development and implementation, plant floor information systems, and MES. He has more than 30 years of experience serving and managing manufacturing enterprises, and was a founder of Integrated Production Systems. He's the author of several books, most recently Collaborative Manufacturing: Using Real-Time Information to Support the Supply Chain (CRC Press, 2002).

Major Manufacturing Systems |

Planning Systems Execution-Level Plant Floor Systems Device and Process Control Systems |

Resources |

For more information about MESs, see www.mesa.org. The Manufacturing Enterprise Systems Association (MESA) is a vendor/user association that is focused on manufacturing systems applications. |

About the Author(s)

You May Also Like