strong water splashing over white background

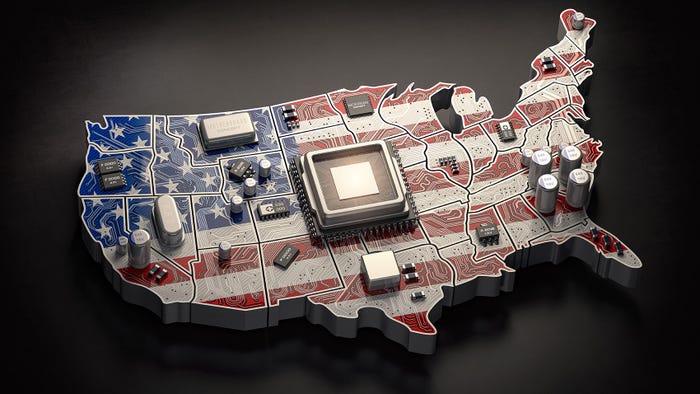

IT Infrastructure

What is Liquid Cooling and How Can It Help Data Centers?What is Liquid Cooling and How Can It Help Data Centers?

The heat loads of modern data centers are exceeding the capabilities of air-cooling technology. Liquid cooling may be the solution.

Never Miss a Beat: Get a snapshot of the issues affecting the IT industry straight to your inbox.

.jpg?width=700&auto=webp&quality=80&disable=upscale)

.jpg?width=300&auto=webp&quality=80&disable=upscale)